Highlights Phase I

A3 Minimization of Vehicular Energy Demand

Lab-scale high volume fabrication of lightweight thermoplastic composites

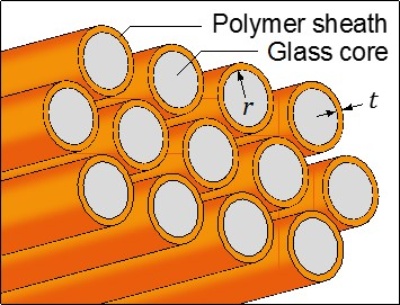

The feasibility of processes suited for high volume fabrication of lightweight thermoplastic composites has been assessed and demonstrated in the laboratory. Methods tested include low viscosity melt impregnation (in-plane and out-of-plane) and direct consolidation hybrid yarn. The characterization of first prototype materials has started.

Bicomponent fibers for thermoplastic composites (pdf)

Melt impregnation of carbon fibre fabrics by injection moulding (pdf)

Successful fabrication of a new bioinspired composite

The developed approach for the fabrication of high-performance composites involves the magnetic assembly of TiO2-coated alumina platelets into ceramic green bodies exhibiting a brick and mortar microstructure. Subsequent hot-pressing produces interconnected mineral scaffolds and infiltration with an organic phase to form a nacre-like composite material.

Demonstrator parts fabricated using promising approaches (pdf)

3D printing of heterogeneous bioinspired composites (link)

!!! This document is stored in the ETH Web archive and is no longer maintained !!!