Nature-inspired super stiff and tough composites

- 12/12/18 10:00 AM

- Kirsten Oswald

Complex Materials Group sheds light on the damage resistance of nacre-like materials

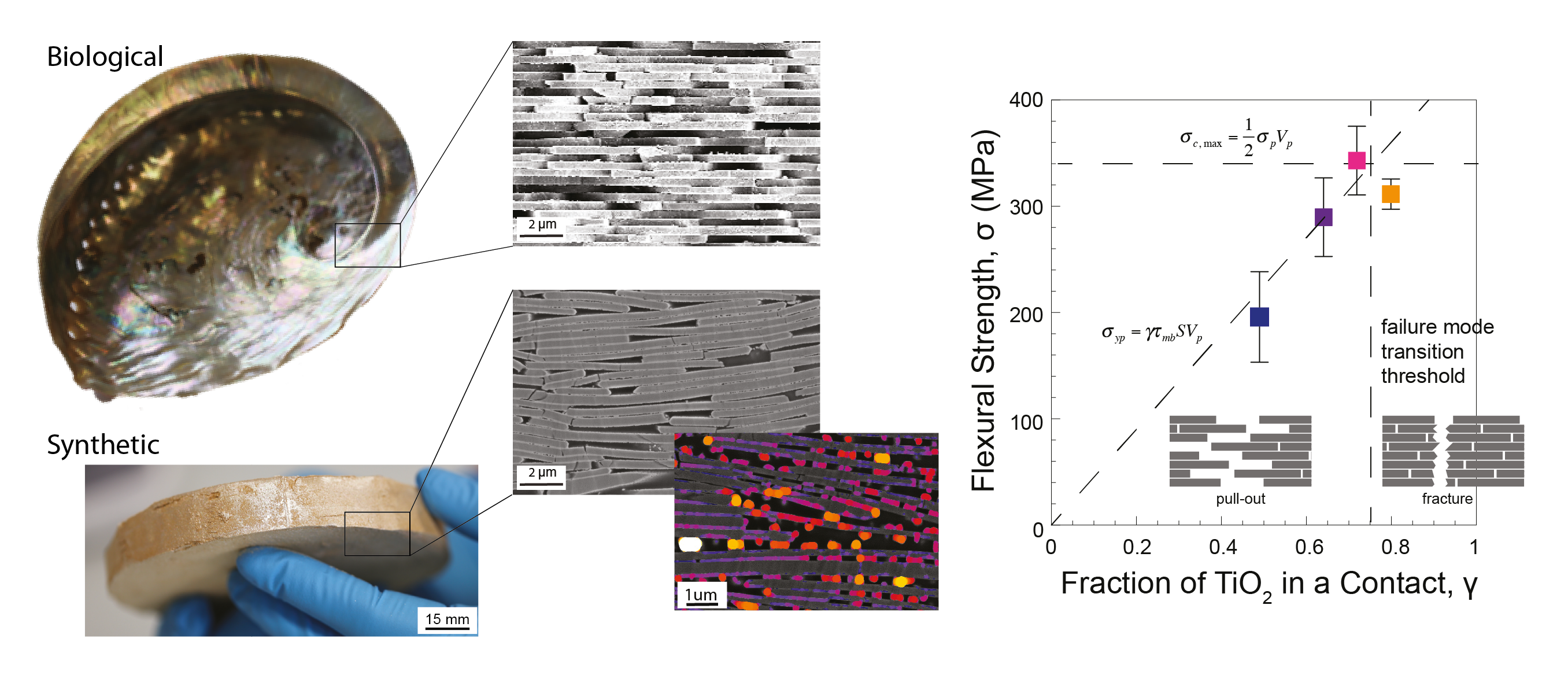

Researchers in the Complex Materials Group (ETH Zurich) have developed a novel material based on biological structures found in nature that are as stiff and tough as the highest performance composite materials today. The study was inspired by nacre, also known as mother of pearl, which is a natural material with remarkable fracture toughness whilst being very lightweight. Its characteristics are due a structural hierarchy that assembles brittle ceramic nanoparticles into very resistant and rigid layers that can delocalize damage, similar to a brick-and-mortar type construction.

By focusing primarily on this structure and not only on the chemistry of the material helped to develop a method to imitate the brick-and-mortar arrangement found in nacre (see figure below). This was done by aligning alumina platelets through magnetization, interconnecting them with titania mineral bridges and infiltration with an epoxy organic phase. Adjusting the platelet-bridge interactions resulted in a material that is comparable to state-of-the-art composites with outstanding mechanical properties. Furthermore, researchers were able to reveal the relationship between mineral bridge density and important fracture properties. This is a major design principle of strong and tough biological composites. Thus, these insights could lead to designing future high-performance materials that combine stiffness, strength and damage tolerance while maintaining a low weight.

For more information, contact Dr. Kunal Masania from the Complex Materials Group or read the corresponding paper, which was published in PNAS recently. This research was carried out in the framework of SCCER Mobility Capacity Area A3.

!!! This document is stored in the ETH Web archive and is no longer maintained !!!